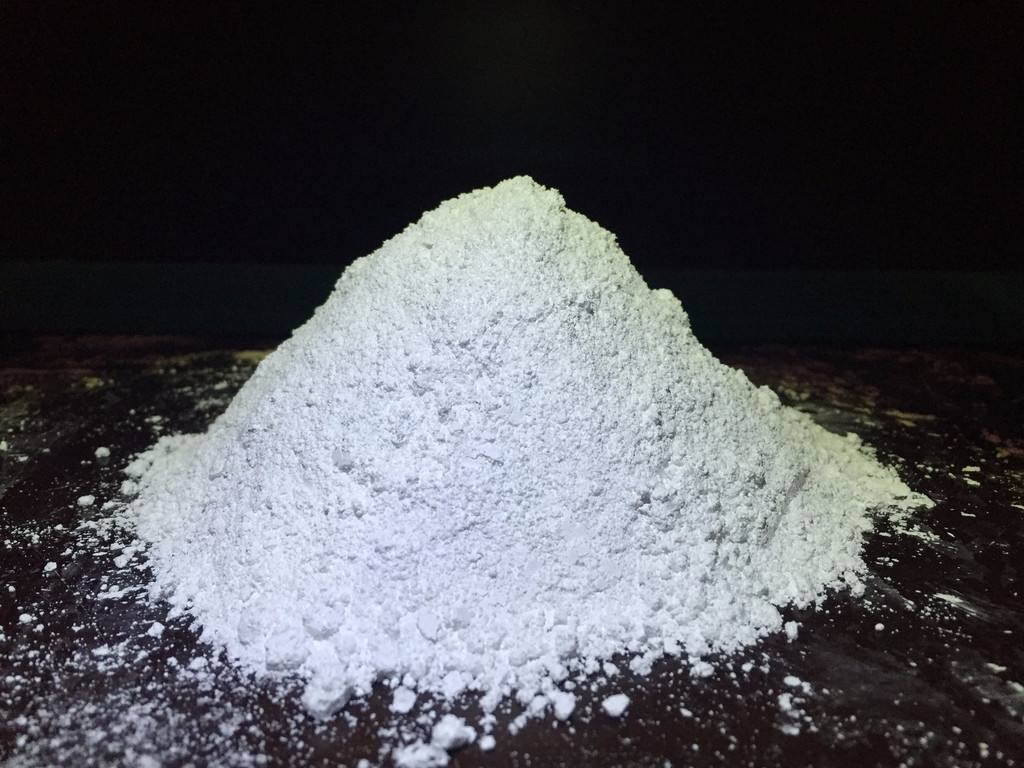

Application of superfine calcium carbonate in industry:

Because of its high whiteness, ultrafine calcium carbonate can play a skeleton role in products, improve the hardness of products, and improve the surface gloss and smoothness of products. It can also replace expensive white pigments.

Superfine calcium carbonate can be used as fillers for high-grade cosmetics, soap, facial cleanser, children's toothpaste, etc. In industry, superfine calcium carbonate is an important component in culture medium and calcium source additive. As a buffer for microbial fermentation, it is used in the production of antibiotics and plays a certain pharmacological role in painkillers and gastric drugs.

In addition, the higher the oil absorption value of ultra-fine calcium carbonate used for rubber, the better the infiltration and reinforcement of calcium carbonate for rubber. Through application, it is found that among the ultra-fine calcium carbonate with different crystal shapes, the chain type of ultra-fine calcium carbonate has the best reinforcing effect on rubber.

The plastic industry is one of the biggest users of the superfine calcium carbonate industry in China, and it is also the field with mature application technology. Ultrafine calcium carbonate to increase volume plastic products, reduce cost and improve the stability, hardness, and stiffness, improve plastics processing performance, improve its heat resistance and improve plastic astigmatism resistance, abrasion resistance, smoothness, and toughening effect of notch impact strength and mixing viscous flow resistance in the process of the has obvious effect.

By applying found that plastic special ultra fine calcium carbonate with cubic shape crystal shape of application effect is best, generally cube crystal shape of product of oil absorption value is low, high oil absorption value chain shaped crystal shape products, due to the plasticizing agent will be used for plastic processing, if the calcium carbonate oil absorption value is high, the amount of plasticizer absorption also big, plastic processing performance will be worse. For the superfine calcium carbonate used for plastic filling, proper surface treatment agent and corresponding activation method should be selected to improve the dispersibility of the product and prevent secondary coagulation. Due to particle agglomeration, the actual particle size of calcium carbonate product is much larger than that of the original particle size. However, due to limited mixing shear force during plastic processing, the agglomeration is not easy to break, which is bound to lead to local defects, and its application effect is not as good as that of ordinary calcium activated carbon.