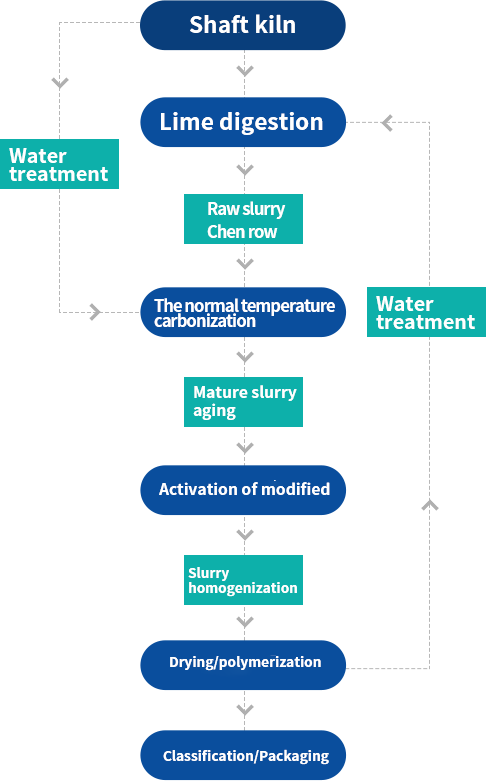

Nanometer calcium carbonate production process

1. Select high-quality limestone raw materials for forging and burning, and obtain calcium oxide and carbon dioxide through strict process control;

2. Calcium hydroxide digestion solution was generated through digestion reaction, which was crushed under the action of high shear force. After multi-stage rotary solution separation, impurities and coarse particles were removed to obtain refined calcium hydroxide suspension;

3. Carbon dioxide gas is injected into the refined calcium hydroxide suspension, and specific additives are added to control the crystal shape, temperature, stirring and pressure. After complete carbonization, calcium carbonate slurry with different crystal shapes can be obtained;

4. By coating, drying and compounding, etc. of calcium carbonate slurry, the corresponding process can be adjusted according to the requirements of different industries to obtain the corresponding nano calcium carbonate products.